- BaoZhu Str. 8, Economic Development Zone, XianAn District, XianNing City, 437000, Hubei Province, China

Where to Buy Magnesium Alloy Die Casting Online – A Complete Guide

Where to Buy Magnesium Alloy Die Casting Online – A Complete Guide

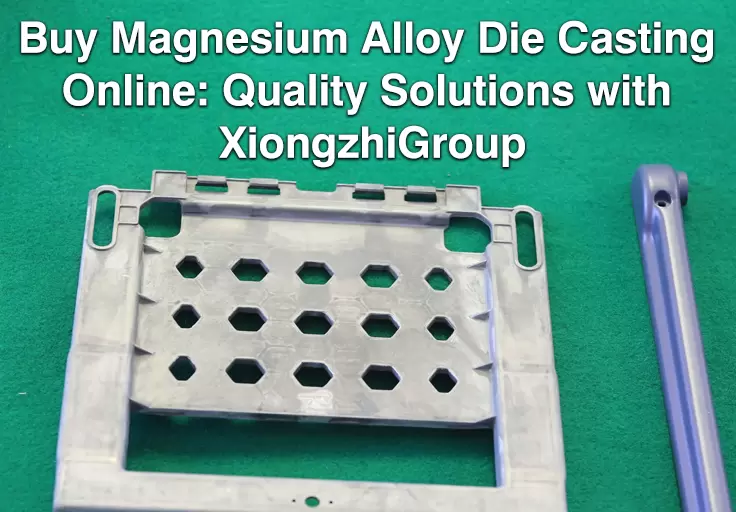

In today's manufacturing world, Magnesium Alloy Die-Casting has become a revolutionary tool, making an industry for itself, especially in demanding places where lightweight, durable, and high-precision parts are required. Magnesium happens to be the lightest of structural metals but has impressive mechanical strengths, good thermal conductivity and high resistance to corrosion. By die casting, complex shapes are made possible with close tolerances and added durability. That is the reason why it is used widely in Train Seat Components, Automotive & Lighting Applications, right down to consumer electronics; it gives businesses the best chance of quality, reliability, and cost-effectiveness when choosing the right online supplier.

Where to Buy Magnesium Alloy Die Casting online

However, online searching will really bring many suppliers who make magnesium alloy die casting. Not all however can provide high-quality and precise magnesium alloy die casting from whom a transport, automotive, or electronics industry could demand. Hence, a perfect partner that would grant their finished products and even provide High-Precision Mold Design, DFM (Design for Manufacturing), and Prototype Die Casting services would be best for most of these companies. XiongZhiGroup fits perfectly in here because it offers complete solutions under one roof with a proven track record in Magnesium Alloy Die Casting for global industries.

XiongZhiGroup – Manufacturing Expertise You Can Trust

XiongZhiGroup Manufacturing Expertise has built a reputation by providing innovative die casting solutions that are tailor-made to client requirements. Their services exceed simple casting, into DFM, wherein company engineers analyze designs for manufacturability and cost efficiency, Prototype Die Casting to validate product performance before mass production, and High-Precision Mould Design to guarantee consistency in complex geometries. Customers from Automotive & Lighting Applications, as well as railway systems, are assured of top-quality components that are delivered on time and within budgets.

Train Seating Components and Their Significance

One of the principal beneficiaries of magnesium die-casting is the rail industry. With high-performance trains, it becomes crucial to reduce the overall weight of the train and make the seating as strong and lightweight as possible without compromising passenger comfort and safety. Long-term performance under safety benchmarks can go on for a long time with durable magnesium frames offered by XiongZhiGroup. Because they manufacture accurate and corrosion-resistant Train Seat Components, most international railway operators view them as trusted suppliers.

Die Casting and Automotive & Lighting Applications

The need for producing lightweight vehicles has never been so high as today. Using dies cast in magnesium allows the manufacturers to construct strong yet light space components that directly influence fuel efficiency and emissions. Also, thanks to its excellent heat resistance, die-cast magnesium finds good application in engine parts and lighting housings. Joining hands with XiongZhiGroup enables automobile manufacturers to realize designs that are at the forefront of performance, safety, and sustainability.

Highly Precise Mould Design Importance

Mould creation is one of the most essential parts of die casting, the High-Specification Mould Design ensuring that each part matches the exact criteria needed by the client. Poorly designed moulds create defects as well as waste material along with costs. At XiongZhiGroup, state-of-the-art software and engineering know-how are used to create robust moulds for the best results that are never-ending. It is most especially important in railways and automotive, where even the slightest mistakes can lead to dire consequences.

DFM (Design for Manufacturing)

Before the start of production, designs are optimized by DFM (design for manufacture), which means removing unnecessary complexity, improving manufacturability, and saving the company money over time. The engineering team at XiongZhiGroup will work closely with customers in strategies to ensure practicality and efficiency in the designs for mass production, as well as making design changes early in the process so that common pitfalls are avoided and best results obtained for the magnesium die-casting process.

Prototype Die Casting for Speedier Innovation

Most companies need to put their designs through preliminary testing prototypes before they can proceed to large-scale production. Prototype Die Casting is the proving ground for the functionality, durability, and performance of such designs. With this capability from XiongZhiGroup, clients move rapidly from concept to prototype, thus mobilizing the energy behind testing, refining, and advancing their designs before full production runs are commenced. This reduces risks, shortens development cycles, and ensures that the final product meets specifications laid out to a high fidelity.

High-Performance Seating Solution for Trains

From modern trains, a trade-off between efficiency and safety should coexist with maximum passenger comfort. High-Performance Train Seating Solutions made from magnesium die-cast components achieve exactly that. XiongZhiGroup constructs very light seating architectures that, in addition to reducing the overall weight of trains, maintain high performances in terms of strength and durability. These solutions meet with international safety standards and inform the transition of the industry to greener and energy-efficient transport systems.

XiongZhiGroup Manufacturing Expertise – Global Leader

XiongZhiGroup Manufacturing Expertise, on the other hand, is setting itself apart by the way it deals with all client approaches. Design right through to delivery is achieved through precision and care. The processes are ISO certified and guarantee compliance at international level, with advanced facilities equipped with die casting machines state of the art, coupled with mold making technology. Most importantly, their customer-first approach avails tailored solutions that give heed to the peculiar challenges each industry faces, whether Automotive & Lighting Applications or Train Seat Components.

Things to Keep in Mind When Ordering from Online

Several factors are necessary when choosing the best place to buy magnesium alloy die casting from online. Firstly, experience and expertise—the supplier must have a good record in handling very complex projects. Technological capabilities such as DFM, High-Precision Mould Design, and Prototype Die Casting should also be available for smooth production as another factor. Another is industry coverage—suppliers must provide solutions for both the automotive and railway industries. Finally, global reach and positive customer feedback are significant signals of dependability. XiongZhiGroup does tick all these boxes, making it an excellent partner.

Order Process with XiongZhiGroup

An order to XiongZhiGroup is straight and transparent. Clients begin with their requirements presented together with technical drawing and specification. Then the engineering team conducts a DFM review to optimize the design for manufacturability. When approved, the company goes to its Prototype Die Casting stage whereby clients could test samples. After final approval, mass production happens followed by delivery loaded full with quality certifications. This structured approach minimizes error and maximizes customer satisfaction.

The Future of Magnesium Alloy Die Casting

If industries gravitate toward solutions that are lightweight and sustainable, then the future of magnesium die casting is brighter than ever. The electric vehicles, high-speed trains, and energy-efficient transportation systems all depend on innovative materials that promise strength in relation to weight. In this light, Magnesium Alloy Die Casting fits perfectly.Promising in innovation and excellence, XiongZhiGroup is set to be at the forefront, continuously developing new techniques and applications for world industries.

Conclusion

If you are searching for where to buy Magnesium Alloy Die Casting online, the best choice is a company that offers complete expertise from design to delivery. Proven capabilities in Train Seat Components, Automotive & Lighting Applications, High-Precision Mould Design, DFM (Design for Manufacturing), and Prototype Die Casting facilities make XiongZhiGroup Manufacturing Expertiseunrivaled in quality and reliability. Their entry into High-Performance Train Seating Solutions and into a very broad spectrum of industrial components makes them the ideal partner for businesses the world over. With XiongZhiGroup, you are buying not only parts but investing in innovation, efficiency, and solutions for future-ready enterprises.

XiongZhiGroup Co., Ltd

XiongZhiGroup Co., Ltd